Agile: Lean, Kanban and Scrum – Scrumban

Lean Software Development

Lean development can be summarized by seven principles, very close in concept to lean manufacturing principles:

1. Eliminate Waste

We want to eliminate all wastage such as unnecessary code and functionality. Many wastages are easy to spot, however many are hard to find. Other types of waste, producing inventory that you can consume, waiting game, obvious dependencies, outdated approval, review process, unfinished stories, bureaucracy, slow/ineffective communication, defects, or task switching, and unproductive meetings. Want to train your agile teams on engineering practices consider CSD Certification Training and BDD for Agile Teams

2. Amplify Learning

We want to create knowledge and amplify learning of the team. Invest in pairing, code reviews, cross-training, coding standards, lunch and learn, and sharing.

3. Decide as late as possible

You know deciding the entire scope 2 to 3 years in advance results into unused functionality. Per standish group study report – on average 45% of functionality you deliver customer never uses them. Also, make the decision as late as possible, specifically when things are very costly to reverse.

4. Deliver as fast as possible

Helps stay ahead with your competition, gain feedback early, reduce risk, reduce unused functionality.

5. Empower the whole team

Respect people. Listen attentively, conduct employee happiness survey, and encourage their input.

6. Build Integrity/quality in

Build your product integrity, quality in every step of the way.

7. See the Whole

Identify your value stream and ensure to optimize entire value steam and not the just the part of it.

- Lean is the foundation for many of the principles and ideas in the Agile methodology.

- With a continuous inspect and adapt approach, lean focuses on the value that the client wants and finds the best method to offer that value while removing waste from the process.

- Lean thinking allowed Toyota to refocus the manufacturing engineer’s attention from a machine’s specific use to the product’s flow throughout the entire process.

- Toyota concluded that the following steps could be taken to achieve low cost, high variety, high quality, and extremely quick throughput times to adapt to changing client desires:

- Sizing machines appropriately for the required volume.

- The introduction of self-monitoring equipment to guarantee quality.

- Arranging the machines in order of operation.

- Inventing rapid setups that allowed each machine to produce tiny quantities of various part numbers.

- Information management could also be improved greatly in terms of accuracy and simplicity. The term, “Lean Software Development” originated from the title of Tom and Mary Poppendieck’s book, “Lean Software Development. (2003)

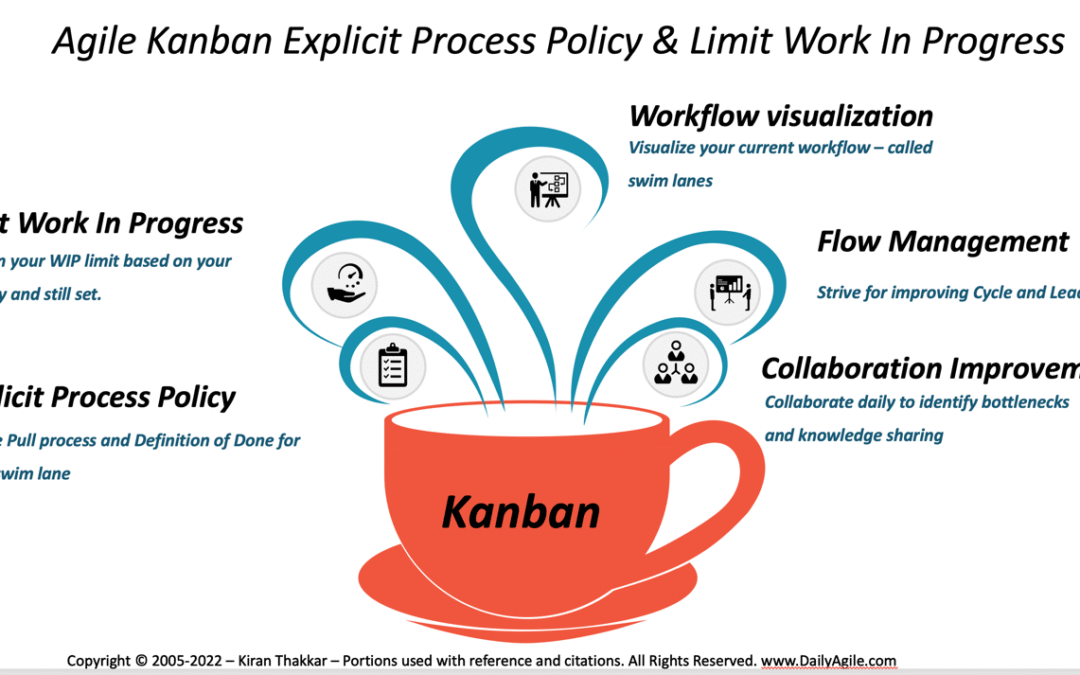

Overview of Kanban

It all started in the first decade of the 1940s. Taiichi Ohno, a Japanese industrial engineer and businessman, developed the first Kanban system for Toyota cars. With the intention of effectively organizing and managing work and inventory at every stage of production, it was created as a simple visualization planning system. Kanban was created in large part because of Toyota’s subpar productivity and efficiency in compared to its American automotive rivals. Toyota used Kanban to increase production while reducing its pricey raw material, semi-finished goods, and completed goods inventories. A versatile and efficient just-in-time production control system is kanban.

A Kanban system would in an ideal world manage the entire value chain, from the supplier to the client. It helps to prevent both supply disruption and overstocking of products at various stages of the manufacturing process. Process observation must be ongoing according to Kanban. It’s important to pay close attention to preventing production-process bottlenecks.

The objective is to shorten lead times for deliveries while increasing throughput. With time, several manufacturing systems have adopted Kanban as a productive technique.

Kanban かんばん

In Japanese the word “Kan” means “visual” the word “ban” means “card“

Kanban is a lean technique used in agile frameworks. It visualizes your current workflow and highlights bottlenecks easily to help you improve your workflow. An elegant workflow is created when all stakeholders can see the entire picture. The goal of Kanban is to expose potential bottlenecks and address them so that flow through the system is organized and optimized for the sake of efficiency.

Source: Anderson, D.J. (2020): Kanban: successful evolutionary change for your technology business. Blue Hole Press.

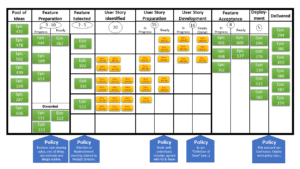

In Kanban

- Work from prioritized backlog

- Visualize every step – make invisible visible – You can use digital visualization or physical board with cards or post-its. It emphasizes the flow and continuous delivery of work.

- Flow Management – Measure your lead and cycle time

- PULL not PUSH work from one workflow state to the next rather than push work to the next state.

- Start where you are and move toward continuous, evolutionary improvement.

- You goal is to provide constant flow of delivery through the system.

Why Kanban?

- Simple and lightweight to implement – Kanban requires minimal process change and no major organizational disruption, making it easy to adopt and scale across teams.

- Data-driven metrics to identify bottlenecks early – Built-in metrics such as cycle time, lead time, and work-in-progress limits help teams detect constraints before they impact delivery.

- Reduced time to market – By improving flow and minimizing hand offs, Kanban enables faster delivery of value and quicker response to customer needs.

- Increased flexibility and adaptability – Kanban allows teams to re-prioritize work dynamically without disrupting delivery, making it ideal for changing business environments.

- Improved collaboration and transparency – Visualizing work enhances shared understanding, aligns stakeholders, and improves communication across teams and functions.

- Fits multiple types of work and industries – Kanban works well for operational support, marketing, sales, infrastructure, product development, and service-based work across industries.

- Enhances flow within iterations or sprints – Kanban practices can be applied within Scrum or sprint cycles to expose mini-waterfalls, reduce waste, improve flow, and increase stakeholder visibility.

- Ideal when the future is uncertain – When long-term planning is unreliable, Kanban enables continuous planning and decision-making based on real-time demand and capacity.

Why not Scrum and Kanban (ScrumBan)?

There is ongoing debate in many organizations around Scrum vs. Kanban—but why choose only one? Instead of treating them as competing frameworks, teams can apply the strengths of both through Scrumban, a hybrid approach that combines Scrum’s structure with Kanban’s focus on flow and continuous improvement.

Scrumban leverages Scrum’s directive elements—such as defined roles, cadence, and planning discipline—to maintain alignment and agility, while using Kanban as a process improvement tool to optimize workflow, limit work in progress, and enable continuous enhancement. This model is particularly well suited for maintenance and support environments, where work is unpredictable and user stories or ad hoc tickets arrive regularly from multiple sources.

By managing team workflow with Scrumban practices, organizations can ensure that each user story or support request is completed as quickly as possible, while encouraging collaboration, transparency, and ongoing improvements to delivery flow.

When to consider ScrumBan?

Scrumban is especially effective in environments where work is dynamic, unpredictable, or flow-based rather than driven by fixed plans. Consider Scrumban in the following scenarios:

- Ongoing maintenance and support projects

Ideal for teams handling continuous work streams where priorities shift frequently. - Rapid, event-driven work

Well suited for help desk and support teams, on-premises infrastructure, security hardening, packaging, and operational response work. - Initiatives with frequent or unexpected requests

Effective when user stories or ad hoc requests arrive from multiple sources with limited advance notice. - Sprint teams facing high uncertainty

Useful for product development teams working on net-new initiatives while simultaneously managing operational work with many unknowns. - Scrum teams struggling with workflow constraints

Appropriate when Scrum is challenged by uneven flow, dedicated resource constraints, or rigid processes that limit responsiveness. - Continuous improvement communities

Supports improvement teams operating during or after a Scrum rollout to refine processes and optimize delivery. - Non-IT and enterprise functions

Applies well beyond IT, including Agile marketing, HR, sales, finance, business operations, compliance, risk, regulatory, and DevSecOps teams.

Scrum |

Kanban |

| It works well in project and product environments (new product development and product enhancements). | It is mostly used in, Non-IT, Discovery, and/or operational environments (maintenance and support). |

| Scrum prescribes iterations (sprints) Timebox | Sprints are not required. In fact, it is hard to plan an iteration in an operational environment due to frequent ad-hoc requests and many dependencies outside of your control. The team can perform some level of planning and retrospection at regular intervals. |

| Scrum defines three (3) roles: Scrum master, product owner, and developer. | No roles are defined. However, teams often select the role of the board owner (person who looks after the Kanban board, someone who can prioritize your input queue). |

| Scrum limits number of items taken into an iteration. No changes are allowed if the iteration is in progress. Focus on Sprint Goal. | Kanban limits Work in Progress (WIP). For example, no more than two items can be worked at by a skill set or within workflow step. Q. How do we decide WIP limit? |

| In Scrum, requirements/stories must fit into a single sprint in most cases. Large requirements must be broken down into smaller pieces of no more than one sprint. | There is no explicit need to break the requirements down. But measuring lead and cycle time forces the teams to work with smaller requirements. |

| Scrum prescribes Five (5) events: Sprint, planning, daily scrum, review, retrospective. | No requirement for daily scrums. However, many teams find useful to quickly review of their Kanban Board regularly. |

| Scrum requires Stable cross-functional teams with size limit up to 10 members. | In Kanban, your team does not have to be cross-functional. A single board can be shared and managed by multiple teams or Multiple kanban boards can be managed by one team. |

Conclusion

Scrumban brings together the strongest elements of Scrum and Kanban to create a balanced and sustainable delivery model. It combines Scrum’s focus on team collaboration and goal-driven execution with Kanban’s emphasis on limiting work in progress to optimize capacity and flow. The result is a system that supports a sustainable pace of work while improving predictability and responsiveness.

By promoting continuous throughput and end-to-end visibility across the development process, Scrumban enables teams and leaders to make better decisions, reduce bottlenecks, and deliver value faster. Rather than choosing between structure and flexibility, Scrumban provides a practical approach for organizations seeking continuous improvement and business agility in complex, real-world environments.

Next Steps

Are you looking to train your Operation, Business, PMO and agile teams on how best to incorporate kanban techniques as part of your digital transformation? We offer customized Lean Kanban with Agile management for IT and Non-IT. Partner with DailyAgile and let us help you accelerate business agility, check out our upcoming workshops at: https://dailyagile.com/all-courses/. Contact us, if you are looking for free 1 hour webinar or agile questions and answer session with your agile leaders. We wish you best luck in your agile journey.

By Kiran Thakkar, 1.800.758.AGILE(2445)